Description

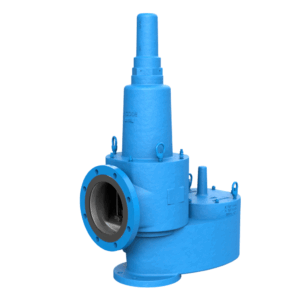

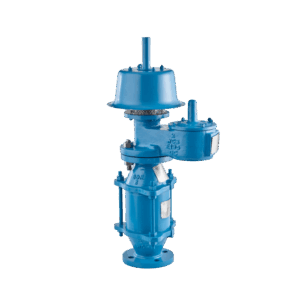

Pressure/Vacuum Relief Valve w/ Pipe-Away

Model: 1220A

Description

Model 1220A is used for pressure and vacuum relief where vapors must be piped away. Escaping vapors are piped away through a flanged outlet connection. This helps to provide increased fire protection and safety.

Features

The flanged outlet connection allows escaping vapors to be piped away, instead of released directly to the atmosphere

Peripheral and central seat guides ensure reliable, repeatable performance

A wide seat and air-cushion seal keeps leakage low long after the valve is put in service

Self-draining housing body and drip rings protect seating surfaces from condensate and freezing, increasing operational reliability

Fluoropolymer seating diaphragms are standard to minimize sticking caused by resinous vapors and atmospheric moisture

Specifications

Size: 2″ (DN 50) through 12″ (DN 300)

Material: Available in aluminum, carbon steel, stainless steel, fiberglass and other materials

Pressure: 0.5 osig to 15 psig (2.15 mbarg to 1.03 barg)

Vacuum: 0.5 osig to 12 psig (2.15 mbarg to 827 mbarg)

Certification: ATEX and PED Approval

Options

150# ANSI, PN10, PN16, JIS drilling classes available

Buna-N, Fluoropolymer, FKM and other seating diaphragms

Steam Jacket

Spacer

Technical Documents for Download (PDF)

Model 1220 Series Datasheet

Valves & Tank Equipment

General Arrangement Drawing 1220A

IOM for Models 1200A, 1220A, 1260A, 1300A, 1360A, 2300A

IOM for Models 1200A, 1220A, 1260A, 1300A, 1360A, 2300A, 1720A, 1760A (Fiberglass)